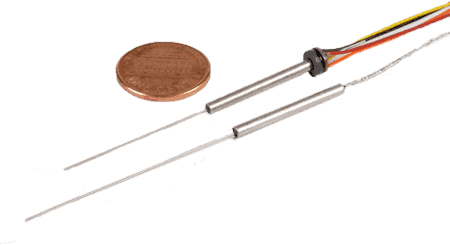

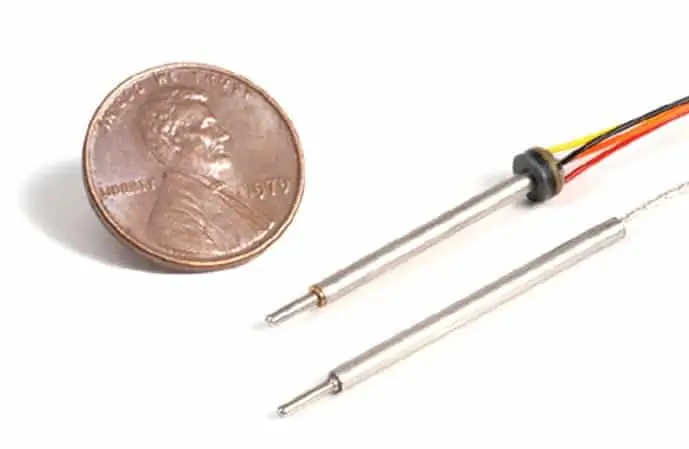

We design & manufacture the world’s Smallest Full Bridge LVDT.

Only 2.3 mm (0.09″) diameter, layer Wound for superior stability,

linearity and repeatability.

Our micro miniature LVDT’s full stroke ranges from +/- 1mm (0.04”) up to +/-8.5mm (0.33”).

Singer Instruments Miniature LVDT Sensors

What is an LVDT Sensor?

An LVDT or linear variable displacement transformer is a type of electrical sensor used to measure linear displacement or position. It is a robust, absolute linear position transducer that is essentially frictionless. LVDTs have a virtually infinite cycle life when correctly used. In particular, AC-operated LVDTs do not contain any electronics so they can be designed to operate at very low or extremely high temperatures (up to 650 °F (1200 °C) and in harsh environments. They are capable of withstanding very high vibration and shock levels.

The low mass of LVDT cores makes them well suited for fast response dynamic measurements. Because the low-mass core floats freely within the housing, there is no friction between the core and the housing. This is ideal for measurements where friction can cause a change in dynamic response and for measurements where stiction can cause inaccuracies. The low mass of their cores also makes these miniature LVDTs well suited for high response dynamic measurements.

Because the LVDT has no moving parts and no friction, it has a nearly infinite mechanical life. When used in inaccessible locations like nuclear plants, embedded in structures for strain monitoring, or installed in choke valves on the seabed, LVDTs continue their operation many years or even for decades.

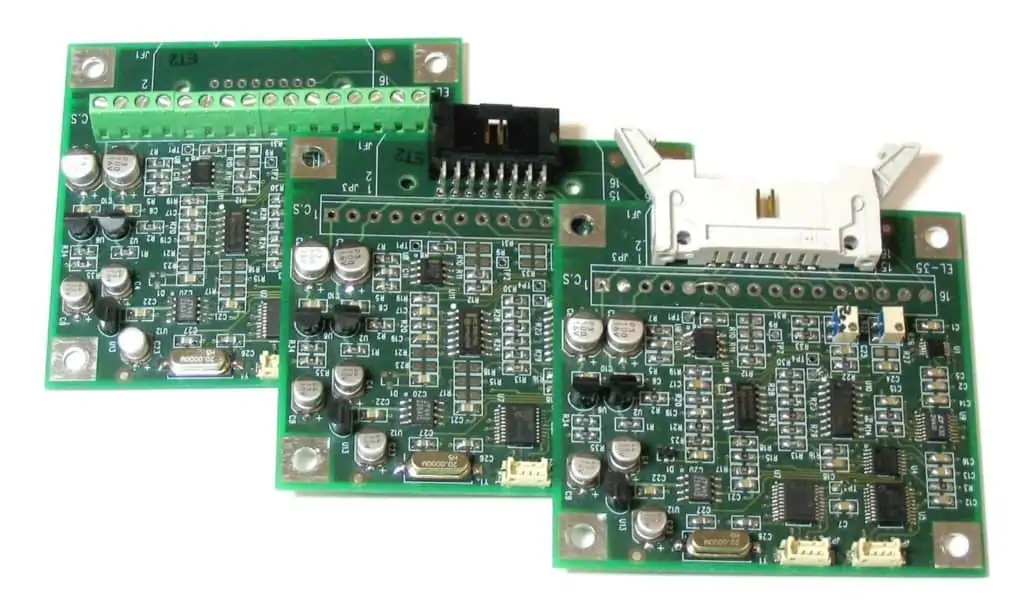

Singer Instruments manufactures a wide range of LVDTs to suit any application, such as AC and DC variants, gauge heads, and spring-loaded.

Singer Miniature LVDTs

Designing and producing an extremely small LVDT requires considerable know-how and experience which is not available to most LVDT manufacturers. Many applications require LVDTs which are much smaller than the standard ranges available on the market.

We manufacture micro-miniature LVDTs that have full stroke ranges from +/-1 mm (0.04”) with diameters up to +/-8.5 mm (0.33”). These miniature LVDTs can be used in very tight or inaccessible spaces where you can’t use standard sizes.

As part of this range of already tiny LVDTs, we manufacture the world’s smallest, full-bridge, LVDT that is only 2.3 mm (0.09″) in diameter. This LVDT sensor is layer-wound for superior stability, linearity, and repeatability. These transducers have low hysteresis and excellent repeatability.

Benefits of Singer Instruments LDVT Sensors

Singer’s range of micro-LVDTs embodies all of the benefits mentioned above in a truly miniature package.

Even if you switch off the power, when you power-on the LVDT again, it provides the same measurement and no positional information is lost. One of the biggest advantages of Singer LVDT sensors is the high repeatability once properly configured. Also, any non-linear motion of the core will not affect its measuring accuracy.

We have micro-sensors that suit a wide variation in environments, such as high pressure, wide temperature range, and wet conditions.

In short, Singer miniature LVDTs are designed for high-resolution, economical, and reliable position measurement in extremely tight spaces and harsh environments.

LVDT Applications

LVDTs are widely used in applications, such as power turbines, hydraulics, automation, aircraft, satellites, nuclear reactors, and many others. They are commonly used for position feedback in servomechanisms and automated measurement in machine tools, and many other industrial and scientific applications. They are commonly used as absolute position sensors.

Here are some of the industries that use our LVDTs:

- Robotic systems—miniature control elements

- Micro-mechanization—force, torque, and joint control

- Optical—linear and angular positioning

- Medical—micro-motion, deformation

Factors that Affect Accuracy

Singer Instruments LVDTs is a world leader in high-accuracy sensors. We produce a wide range of sensors that uniformly provide:

- Low non-linearity

- Accurate calibration

- Low retrace error

- High repeatability

- High resolution

Contact Singer Instruments for your LVDT Requirements

Apart from our standard miniature ranges, we are uniquely positioned to offer you a full customization capability and tailor-made solution.

If you need a customized, miniature LVDT, let our specialized team of engineers work out a solution that meets all your requirements. We have the knowledge and experience in producing miniature LVDTs with extremely small strokes and diameters to allow us to provide a solution that suits you.

Call Singer Instrument and Control on +972-4-8578880 to discuss how our unique skills and experience can benefit your business.